INVESTIGATION OF MACRO- AND MICROSTRUCTURE OF ALLOYS

Purpose of the work: to acquire skills at macrostructural analysis of ferrous and non-ferrous alloys, both on fractures and special macroetched sections; to study the microstructure of hypoeutectoid, eutectoid and hypereutectoid carbon steels, grey, malleable and nodular cast irons; to investigate the influence of graphite inclusions’ shape on mechanical properties of cast iron. Theory. Crystal is formed during the solidification process in castings and ingots may be of various shapes, arrangement and orientation primarily because of cooling nonuniformity. Due to the selective crystallization detrimental impurities (sulphur, phosphorus, etc) are displaced to the grain boundaries. This process is usually called the dendrite liquation. In case of protracted crystallization impurities with low density migrate into the upper part of the ingot. Thus, so-called zone liquation is developed. Liquid metal has a higher unit volume than a solid one and does not solidify simultaneously throughout the ingot. Therefore, a cavity, called a pipe, is formed in the part of the ingot that freezes last. Shrinkage porosity is also the result of the nonuniform volume decrease. Besides, blowholes and gas porosity are formed in consequence of the decreasing gas abilities to be dissolved in solid metal in comparison with the molten one. Further treatment of metal products: hot and cold working, welding, heat-treatment or chemical heat-treatment, — also influences greatly upon metal structure and, correspondently, its mechanical and service properties. Thus, macro- and microstructural analysis is considered to be among the main quality control methods in metallurgy and machine-industry. Macrostructure is the constitution of a metal or an alloy investigated by the naked eyes (visually) or by low-power magnification (not more than 50x). Macrostructural analysis is employed to disclose surface defects (cracks, porosity, inclusions). It also enables a general picture of the crystalline structure of a metal to be obtained for the large volumes. It may be performed either by external examination and control or on special macroetched sections (specimens, cut of large billets or parts, ground on one surface and then etched with special reagents), called templets. The visual inspection can disclose surface cracks, gas and shrinkage porosity, slag inclusions and other defects. Fracture examination gives an idea of fracture pattern. Brittle materials are characterized by crystalline fracture. In this case fragments of cleavage plains with specific luster occur on fracture surfaces. Brittle fracture, in turn, is divided into intercrystalline (crack passes trough the grain body) and interfacial (crack travels along the grain boundaries) fracture. Investigating brittle fracture it's possible to make a general conclusion concerning the grain size and shape. Another type of fracture is the tough one (the result of a tough failure). It is usually characterized by fiber (fibrous) fracture surface. Because of the significant strain it is almost impossible to assess the grain size and shape on such fracture. One can frequently come across intermediate fracture when brittle and tough regions are mixed up on the same fracture. Fatigue fracture is typical to the parts and components exposed to alternate repeated load (shafts, axles, gears, etc). It consists of the crack initiation zone, the slow fracture propagation zone and the ruptured zone. Special macroetched sections are prepared for the internal structural analysis and disclosing internal defects. They are etched with special reagents (etchants). The action of these etchants is based on their ability to dissolve and colour differently various structural components of an alloy. Examination of a macroetched section enables to assess the shape, size and arrangement of crystals in "as cast" structure; the direction of grain flow lines (deformed crystallites in, for instance, smith of closed-die forgings (Fig. 1.1), chi1led zone in cast iron and hardened layer in steel; chemical nonhomogeneity of an alloy caused by solidification process or resulting from heat-treatment or chemical heat-treatment; shrinkage porosity, blowholes, cracks etc. Carbon, phosphorus and sulphur are the most nonhomogeneously distributed elements in steels. To reveal the distribution of sulphur in steel the Baumann's method is commonly used. A sheet of glossy bromide photographic paper, wetted in a 5%aqueous solution of sulphuric acid, is applied to the section. As a result of the reaction between sulphurous compounds on the steel surface and sulphuric acid the hydrogen sulphide is obtained: FeS(MnS) + H2SO4= Fe(Mn)SO4 + H2S

a b c Fig. 1.1. Macrostructure of a steel: a – “as cast”; b – forged; c – rolled

The hydrogen sulphide reacts with the silver bromide of the photographic emultions:

H2S + 2AgBr = Ag2 S + 2HBr

After being fixed with hyposulphite, the paper will darken in sulphur-rich areas owing to the formation of silver sulphide (Fig. 1.2).

Fig. 1.2. Chemical nonhomogeneity (liquation) of sulphur in steel

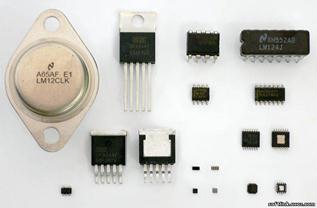

Microstructural analysis (micrography) is the investigation of metal structure with an optical metallurgical microscope in which a specimen is observed in reflected light and magnification ranges from 50X to 2000X. The electron microscope with magnification up to 1000000X and over is also extensively used to study the structure of metals. Microscopic structural analysis enables the number, size, shape of the grains to be determined, as well as the arrangement and mutual ratio of phases that make up the alloy. It also makes possible to detect very fine defects (flows) in the metal (nonmetallic inclusions, microcracks, etc). To conduct a microscopic investigations a microsection of the metal to be analyzed is prepared. At first the microsection is investigated without preliminary etching to reveal porosity, microcracks, nonmetallic and graphite inclusions. Microstructure of a metal is revealed by etching the specimen (microsection). The most commonly used etchant is an alcoholic solution of nitric acid (5 ml HNO3 per 100 ml of alcohol). The etchant causes selective dissolution of grains and their boundary regions in homogeneous alloys, as well as metallic or other phases in heterogeneous alloys. The main structural components of the iron-carbon alloys are following: ferrite, austenite, cementite, ledeburite and graphite (Fig. 1.3, 1.4, 1.5).

a b c

d e Fig.1.3. Microstructure of a steel: a – ferrite, 100x; b – ferrite + pearlite, 1000x; c – pearlite, 500´; d – pearlite + cementite (white), 1000´; e – austenite, 100´

The solid solution of carbon in alpha-iron is called ferrite. Depending upon the temperature the carbon content in ferrite ranges from 0.006% at room temperature to 0.02% at 727°C. It possesses high plasticity and rather low hardness (HB 800…1000 MPa). Austenite is the carbon solid solution in gamma-iron. It contains 0.8% of carbon at 727°C and 2.14% at 1147°C. Austenite has rather high plasticity and hardness (HB 1700…2200 MPa).

a b c Fig. 1.4. Microstructure of chilled cast irons: a – hypoeutectic: pearlite (dark) + ledeburite; b – eutectic: ledeburite; c – hypereutectic: ledeburite + cementite (white). 100´

Fig. 1.5. Graphite in cast irons: a – lamellar, b – flaky, c – vermicular, d – speroidal (globular); structure of grey (e) and high strength (f) cast irons. 100´

Iron and carbon also form a chemical compound, iron carbide Fe3C, which has been named cementite. It is characterized by low plasticity and high hardness (HB 7000…8000 MPa). Pearlite is a mechanical (phase) mixture (euctectoid). It is obtained by simultaneous precipitation of ferrite and cementite particles from the austenite. Perlite contains 0.8% of carbon and possesses hardness number of HB 1600…2000 MPa. Ledeburite (eutectic) is a mechanical (phase) mixture formed in either austenite and cementite simultaneous precipitation from the liquid metal at the temperature range from 727 to 1147°C, or pearlite and cementite simultaneous precipitation at the temperature below 727°C. It contains 4.3% of carbon and is known to be the main structural component of white (chilled) cast iron. The hardness of this mixture is approximately HB 6000 MPa at room temperature. Graphite is a free carbon possessed low plasticity and tensile strength. The typical feature of grey cast iron is that in its structure the graphite is in the form of lammelas. Grey cast iron has been named so because its fracture appearance is dark grey or almost black. In malleable cast iron the graphite separates out in form of flakes (called temper graphite). The graphite in microstructure of high-strength (nodular) cast iron is of globular (spheroidal, nodular) shape. In the recent time vermicular graphite cast iron (intermediate form between lamellar and globular graphite) has been widely applied in industry (Fig. 1.5). The graphite inclusions may be regarded as internal notches which violate the continuity of the metal. Thus, they reduce the resistance to fracture, the tensile strength and, especially, the plasticity of the cast iron. Average mechanical properties of the steel 45Л with ferrite-pearlite structure and cast iron with the same structure but different types of graphite inclusions are represented in the table 1.1. From the table it's possible to make the inference that globular graphite provides the highest cast iron mechanical properties to be obtained.

1.1. Comparative properties of steel grade 45Л and cast irons

|

a

a

b

b

c

c

d

d

e

e

f

f