Safety and Relief ValvesЗадание 1. Ознакомьтесь с данными ниже словами и выражениями к тексту:

1. safety valve - предохранительный клапан 2. relief valve - разгрузочный клапан 3. spring-loaded - подпружиненный 4. overpressure relief - высвобождение избыточного давления 5. to conserve - сохранять 6. differential pressure - перепад давления 7. to take into account - принимать в расчет 8. to devise - разрабатывать 9. poppet valve - тарельчатый клапан

Задание 2. Прочитайте текст.

Safety and relief valves come to prevent equipment damage by relieving accidental overpressure. This excess pressure may go to atmosphere or discharge to some low-pressure point in the system. Most safety and relief valves are spring-loaded to operate at a set pressure but weighted levers or a combination of levers and springs may also provide the load. In any case, valve loading is adjustable so a fine degree of control can be field set after installation. Confused nomenclature is a problem in this area. The names "safety" and "relief" are frequently used interchangeably - they should not be. Actually, there is a real and important difference between these two types, which their names do reflect if used properly. Safety valves are for the compressible fluids-steam and other gases*.This compressibility demands quick overpressure relief. So safety valves have pop seats and plugs which open rapidly on overpressure, relieving at full flow. They may discharge steam to atmosphere or direct a costly or toxic gas back to the system. Relief valves handle non-compressible fluids - liquids such as water and oil. Immediate full-flow discharge is not needed since a very small flow significantly reduces overpressure. So plug and seat close slowly, discharging back to some low-pressure point in the system to conserve the liquid. Box at right shows why pop-safety valves operate differently from relief valves. In the relief valve, plug area exposed to the overpressure stays constant whether valve is open or closed. So operation is gradual, and degree the valve is open becomes a function of differential pressure. Safety valves, however, have a variable effective plug area. At the instant of opening, the plug area increases, boosting the total opening force against the constant spring load. Actual opening from zero to full flow is fast: the same effect pops the safety valve shut when pressure falls below blow-down level. Safety and relief valves should always be connected directly to the equipment they protect - no intermediate valves and shortest-possible piping. If you're using outlet piping, keep it short, too, with minimum friction drop to prevent chattering when the valve is open. Valve setting must take into account any backpressure. Example: if a safety valve is to open at 100 psig against a constant backpressure of 10 psig, set it at 90 psig to be sure it actually opens when pressure reaches 100. Safety valves have relieving pressures marked on them. Even a slight opening of the valve will allow a substantial proportion of the flow to pass and full flow is given theoretically when the valve is opened rather less than one quarter of its diameter. In practice this would rarely be necessary and the maximum movement is limited to 1/8 in. Several variations of this simple valve have been devised which increase its scope or simplify manufacture. A simple three-way valve can be arranged as Fig. 13 where a hollow plunger serves both to actuate the valve and act as the exhaust port. When the plunger is depressed the end first seals on the flat packing and further pressure then lifts the packing off its seat on the main body. Most three-way poppet valves are,' however, of the twin type, the plungers being actuated by a lever or similar mechanism.

As this is the most that can be done with two poppet valves, a four-way valve for controlling both ends of a double-acting cylinder requires two sets of three-way valves, i.e. four poppet valves in all, although these can be operated by a single control. It will be realized that the complexity of this arrangement makes it comparatively less attractive economically as a four-way valve than as a two- or three-way valve.

Задание 3. Ответьте, верны ли следующие утверждение. Если нет - исправьте.

1. Safety and relief valves have one and the same functions. 2. Most safety and relief valves are spring-loaded to operate at a set pressure. 3. In the relief valve, plug area exposed to the overpressure is changeable whether valve is open or closed. 4. Valve setting must take into account any backpressure. 5. Most 3-way poppet valves are of the twin type.

Текст 4. Designs of Pneumatic Directional Control Valves. З адание 1. Выпишите и выучите следующие слова.

1. to discharge- разгружать, выпускать 2. mushroom valve- тарельчатый(дисковый) клапан 3. on-off- релейный 4. stem- основа 5. O-ring- кольцо О- формы 6. dead space- неиспользованное пространство

Задание 2. Прочитайте текст. Because exhaust air can be discharged directly to the atmosphere without the obvious drawbacks of discharging liquid directly, an air valve, especially if three-way, can be a very simple affair. In practice this is not always realized as circuits often require a valve which connects two or three pipes under pressure. Direct discharge may also be objected to because of noise or the disturbance it may cause of dust etc. Simple valves are, of course, still widely used but the large quantities of valves now sold has made it possible to produce more complicated types without too great an increase in price.

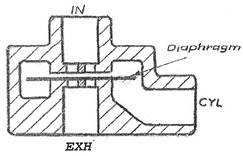

Poppet Valves: These valves are based on the traditional mushroom or miter valve but the design has been adapted to utilize modern synthetic sealing materials such as nylon or synthetic rubber. The simplest design (Fig.12) is an on-off or two-way valve, where the plunger is operated mechanically and the valve is held closed by a spring assisted by the line pressure. The synthetic seating is 1 carried on the stem and an annular counter seating machined at the bottom of the hole in the valve body.

Uses of Poppet Valves: For controlling such things as air drills, two-way poppet valves are an obvious choice because of their simplicity and ease of operation. They may also be preferred for general use again because of their simplicity and ease of servicing. The only part likely to cause trouble is the disc washer-now sometimes replaced by an 0-ring, which can be replaced in a few minutes. The quick-opening characteristics are obviously attractive when a cylinder has to operate at maximum speed. In this case it is probably best to have two three-way valves actually on the inlet ports so that the dead space is reduced. It is likely in practice that these valves would be pilot controlled. That is, each valve would contain a small piston which is acted on by air controlled by a small separate valve and connected to the main valve by a pipe.

Задание 3. Ответьте на вопросы по тексту.

1. What is the characteristic feature of directional control valves? 2. What are traditional mushroom valves based on? 3. What is their simplest design? 4. What is the most preferable for controlling such things as air drills? 5. When are the quick-opening characteristics the most attractive?

Текст 5. Slide Valves Задание 1. Выучите следующие слова.

1. slide valve-золотниковый клапан 2. linear movement-линейное движение 3. spindle- вал, ось 4. slider- ползун 5. in an arc of a circle- по дуге окружности 6. to oscillate- качаться, колебаться

Задание 2. Прочитайте текст и скажите на английском языке о принципе работы золотникового клапана.

The slide valve (Fig. 14} is favoured by a number of markers because of its effectiveness and long life.

It is, however, rather more expensive to make than some competitive makes and |the types of circuit it can be used with are limited to those requiring only four-ways on the valve. The sliding member is formed with a cavity which connects the appropriate end of the cylinder to exhaust whilst the port of the other end of the cylinder is open to the 'valve chest1 which is connected to the air apply. The sliding member is oscillated, either in an arc of a circle or linearly, by a lever or other suitable means. The slider is carefully lapped to the face on the body and if this is done properly the valve remains leak tight for a long time. The slider is held on its seat by the spring and also by the air pressure. It is because there must be a common air supply that this valve can be made with a maximum of four ways.

Текст 6. Spool Valves Задание 1. Выучите следующие слова и выражения.

1. leakage- утечка 2. danger of rust- опасность коррозии 3. layout- расположение 4. impulse-manual- ручное управление 5. silencer- глушитель 6. ample flow- достаточный поток 7. inlet air- входящий воздух 8. rod end- наконечник золотника, штоковая полость цилиндра 9. spool valve- золотниковый клапан

Задание 2. Прочитайте текст.

It is only comparatively recently that spool valves have been used extensively for pneumatics, although they have been standard practice in oil hydraulics for many years. The principle of operation of an oil valve is similar, but for air it is not usual to rely on metal to metal fits to prevent leakage and soft packings are common. Because of the danger of rust, materials must be unaffected by water, so that steel must always be stainless. Oil is also likely to be present either accidentally or deliberately for lubrication, and packings must therefore be oil resistant. The layout of a five-way valve provides inlet and exhaust ports which may be interchangeable - i.e. there can be one inlet and two exhaust ports, or vice versa. Air valves are usually of the two position type and have no central position. They are either spring biased in one direction or require an impulse-manual, mechanical, pneumatic or electric to move from one position to the other. Some makers omit the end seals and the outer pair of ports can then be used only for exhaust. Unlike a hydraulic valve, there is no need to connect the two exhaust ports internally as the either discharge to atmosphere, flow control valves or to silencers. The force to operate a valve with 0-ring seals is 10 to 15 lbs.| and for manual operation a lever is essential. Some makers offer valves arranged so that the spool is pushed direct; this is satisfactory for occasional use but for continual use something which can be grasped and with a load of 5 lbs.max., is essential if the operator is to work without discomfort. Unless very rapid operation of a large cylinder is required, nominal 1/2 in. valve is large enough for all practical purposes, as it is capable of passing about 80 C.F.M, (cubic feet free air per minute) for a pressure differential across the valve of 80 p.s.i. This is equivalent to about 20 h.p. at the compressor. In practice the benefits of an ample flow capacity are often of greatest value when the cylinder exhausts and this can usually be given by a quick exhaust valve which will be described later. This is fitted directly to or very close to, the cylinder port and only a small proportion of the exhausting air passes through the main valve. If the exhaust is taken back through the main valve, the inlet air is building up pressure in the head end of the cylinder, whilst the pressure in the rod end is dying away. It is only when the rising pressure in the head end has reached the diminishing pressure in the rod end that the piston will move and even then it will have to drive out partly pressurized air through the piping and valve passages. If however, a quick exhaust valve fitted the pressure in the rod end gets away much more quickly and the resistance to the air being pushed out as the piston advances is much reduced. The quick exhaust valve can be used with most types of four- and five-way valves.

Задание 3. Ответьте на вопросы по тексту.

1. Why must materials be prevented from water? 2. What materials must be used for these valves? 3. What does the layout of a 5-way valve provide? 4. Do air valves have central position? 5. Why is there no need to connect the two exhaust ports internally? 6. What is the usual capacity of these valves? 7. What happens if the exhaust is taken back through the main valve?

Текст 7. Check Valves. Задание 1. Выучите следующие слова.

1. reversal- обратный ход, противоток 2. flap valve- шарнирный клапан 3. tilting disk- наклонный диск 4. swing disk- поворотный диск 5. to clog- препятствовать 6. check valve- обратный клапан

Задание 2. Прочитайте текст и скажите, в чем принципиальная разница в работе обратного клапана от раннее описанных.

Flow reversal in fluid-handling systems can be used by accidental equipment stoppage or automatic fail-safe devices. This reversal must be promptly and effectively halted, or tanks overflow, rotating equipment over speeds any you're left with local flooding and damaged machinery. Open in one flow direction, closed in the other, check or non-return valves prevent flow reversal)), In design they range from simple, inexpensive swing-disk or flap valves to hydraulically contoured tilting-disk valves for high pressures and high temperatures. "Stop-check" valves do double duty; they operate as check valves, but also can be turned down by hand or motor to assure tight closing. All check valves used in energy systems fall into two basic categories, piston and disk. Piston types, including ball and stop-check valves, have relatively high internal losses because of flow-direction change*- But they do seal tight. Some designs, however, depend on a free-riding piston which can hang up if clogged with dirt or scale after long, continuous operation. In other designs, a bleed line back of the piston helps seat the valve by using down-stream pressure to start it moving. Tilting-disk check valves, including swimming-disk and flap types, keep fluid losses low with almost straight-through flow. They close dependably with slightest flow reversal or even at zero flow. But a tight seal is less sure, especially if valve happens to close against a foreign particle. Some recent high-pressure installations have two check valves in series. A piston type shuts off tight. Followed by a disk type to assure at least partial closure and preclude high-volume flow reversal through the system.

Текст 8. Butterfly Valves. Задание 1. Прочитайте текст о принципе работы поворотной заслонки.

Butterfly valves are certainly not new, but in the last several years they have been receiving increased interest as final control elements. As a basic valve type they offer many advantages and recent improvements have broadened their fields of application. The butterfly is essentially an equal-percentage valve type in the normal control range. Any change in valve travel results in an equal- percentage change in flow. From the viewpoint of change in open-valve area only, this equal-percentage statement would not seem justified. However, approach velocity as well as diverting action of the disk is a function of disk position. Their combined effect, together with change in valve area, produces the equal-percentage characteristic. Butterfly valves will undoubtedly pick up an even larger share of control-valve assignments as more and more engineers become aware of their special advantages.

Текст 9. Quick Exhaust Valve. З адание 1. Выучите следующие слова и словосочетания.

1. quick exhaust valve- клапан быстрого выхлопа 2. exhaust port- выхлопное отверстие 3. velocity- скорость 4. incur- подвергаться 5. bulky- громоздкий, объёмный 6. sintered material- металлокерамика 7. perforated metal disk- перфорированный металлический диск

As mentioned above, the quick exhaust valve is a device for exhausting air from a cylinder without it having to pass through the directional control valve. Various designs are available but all contain a moving member which seals an exhaust port when pressure is applied, but as soon as the directional control valve is operated and air starts to flow out of the cylinder, the moving member is affected by the flow and uncovers the exhaust port. A typical example is shown in fig. 15.

7 Exhaust Air. After compressed air has served its usefulness it is usually passed into the atmosphere. Sometimes exhaust air can be used for ejection of parts after machining. Exhaust blasts can be unpleasantly noisy but fortunately there can be no excuse for this, as efficient silencers are available. These reduce the velocity of the air as it enters the atmosphere and the degree of effectiveness depends on the efficiency with which this is done without incurring the penalty of too much back pressure. Probably the most efficient is the expansion chamber but this is necessary bulky and it is not very popular because of this. More usual are porous tubes, one or two inches diameter, of sintered metal or plastic, or short tubes about twice the diameter of the port with a perforated metal disc fitted in the end.

|

Fig. 14: Slide valve with linear movement. A variation of this valve has a spindle which rotates the slider in an arc of a circle.

Fig. 14: Slide valve with linear movement. A variation of this valve has a spindle which rotates the slider in an arc of a circle.

Fig.15: Quick exhaust valve. The rubber disc is held in the position shown when pressure is applied but is displaced when it is exhausted, so allowing the cylinder discharge direct to atmosphere.

Fig.15: Quick exhaust valve. The rubber disc is held in the position shown when pressure is applied but is displaced when it is exhausted, so allowing the cylinder discharge direct to atmosphere.