Головна сторінка Випадкова сторінка

КАТЕГОРІЇ:

АвтомобіліБіологіяБудівництвоВідпочинок і туризмГеографіяДім і садЕкологіяЕкономікаЕлектронікаІноземні мовиІнформатикаІншеІсторіяКультураЛітератураМатематикаМедицинаМеталлургіяМеханікаОсвітаОхорона праціПедагогікаПолітикаПравоПсихологіяРелігіяСоціологіяСпортФізикаФілософіяФінансиХімія

УКРАЇНА

Дата добавления: 2015-09-18; просмотров: 1052

|

|

| frequent ['frI:kw∂nt] hydrodynamic ['haIdroudaI'næmIk] coupling ['k ʌ plIŋ] environment [In'vaI∂r∂nm∂nt] | thorough [θ ʌ r∂] qualified ['kw ɔ lIfaId] pressure ['pre∫∂] shovel ['∫ ʌ vl] | vinylchloride [vI'nIlkl ɔ rId] ratio ['reI∫Iou] guide [gaId] distinguish [dIs'tIŋgwI∫] |

Hydraulic equipment is very frequently met in road-making, hoisting and transporting devices. The principle of operation subdivides such equipment into two distinct groups:

a) equipment operating on hydrostatic principles, known as volume-displacement drives;

b) equipment operating on hydrodynamic principles, employed in transmissions in the form of fluid couplings and torque converters.

A) In a hydraulic volume-displacement drive the pump builds up a pressure which is transmitted by the working fluid to the piston of a hydraulic cylinder or the rotor of a hydraulic engine.

As distinct from mechanical and electric drives, the operation of a hydraulic system depends largely on the temperature of the environment. Certain units and parts of a hydrodrive should be machined very thoroughly and attended in operation by highly qualified personnel.

The equipment of a volume-displacement drive is employed both in transmission and control systems. The volume-displacement drive has the following principal components: pump, hydraulic engines or cylinders, timer, safety and adjusting valves, fluid tank and connecting pipes.

The pump, which delivers the fluid under pressure, obtains mechanical energy from the engine directly or through a transmission. In the hydraulic cylinder, the piston and the mechanism linked to it perform a reciprocating motion and, in the case of a hydraulic engine, the operating member of the machine is brought into rotational motion. Such an engine is used, for example, to turn the blade of a self-powered grader, to slow the turntable of a crane or of a power shovel, to drive the wheels or the drive sprocket of a crawler chain.

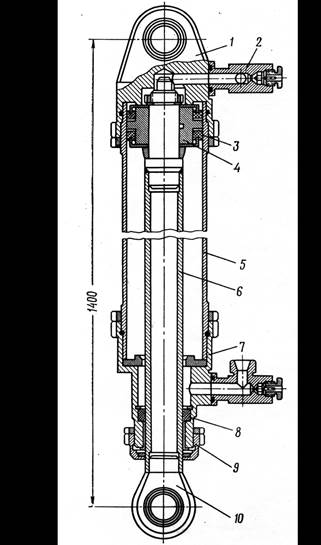

Let’s consider the way of operating a hydraulic cylinder (fig. 1.). The fluid is delivered to the channels in the cylinder covers through flexible hoses. Some hydrodrives use hinged rotating pipe joints. This makes it possible to dispense with flexible hoses, which are the vulnerable spots of the system. The piston and rods are sealed with vinylchloride or rubber packing glands. The gland at the rod hole in the cover keeps dirt out of the cylinder. In the cylinder shown in Fig. 1 the oil can be delivered into the space above or below the piston, enabling the latter to develop thrust either way. Such a cylinder is called a double-action or two-end cylinder.

Let’s consider the way of operating a hydraulic cylinder (fig. 1.). The fluid is delivered to the channels in the cylinder covers through flexible hoses. Some hydrodrives use hinged rotating pipe joints. This makes it possible to dispense with flexible hoses, which are the vulnerable spots of the system. The piston and rods are sealed with vinylchloride or rubber packing glands. The gland at the rod hole in the cover keeps dirt out of the cylinder. In the cylinder shown in Fig. 1 the oil can be delivered into the space above or below the piston, enabling the latter to develop thrust either way. Such a cylinder is called a double-action or two-end cylinder.

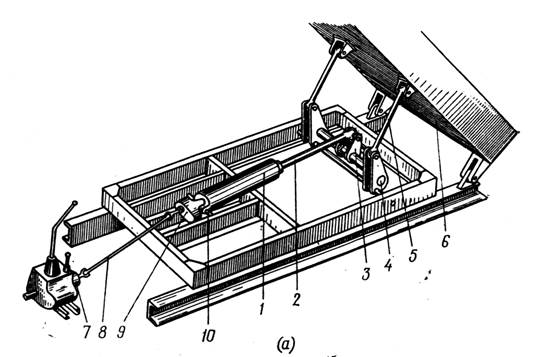

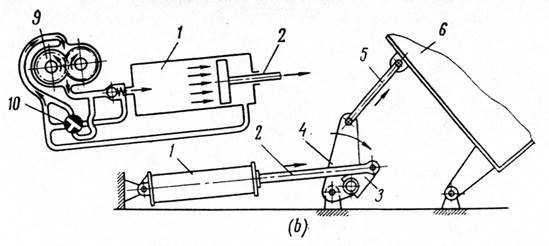

There may be also single-action cylinders. They are employed in the hydraulic hoist of a dump truck, in which the backward stroke of the piston ram is effected by the weight of the load being raised or by the weight of the body (fig. 2.)

Fig. 1. Hydraulic cylinder: 1 – blind cover;

2 – connection; 3 – gland; 4 – piston;

5 – tube; 6 – rod; 7 – cover with a hole for the rod;

8 – collar; 9 – cap; 10 – eye

Fig.2. Lever-type hydraulic hoist of MAЗ-205 dump truck

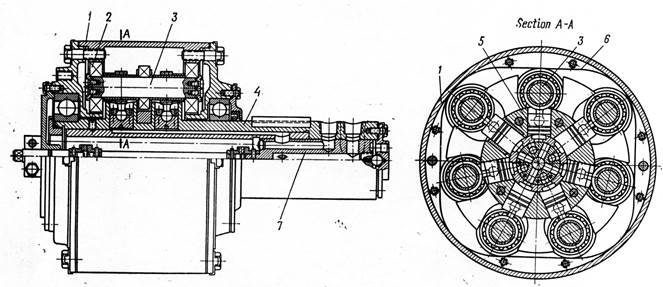

There are also radial-piston hydraulic engines, which are high-torque hydraulic engines. A hydraulic engine with a variable-capacity pump ensures high gear ratios and gives a continuous control of operating member speeds over a wide range. Besides, it automatically protects the prime mover against overloads. This type of engine is employed in power shovels, cranes and other construction and road-making machinery.

The hydraulic engine is designed with movable housing (1) and stationary rotor (4). Seven pairs of rams (5) move in the radially arranged holes of the motor. The working fluid, supplied under pressure, transmits effort from the pistons through the connecting rods to axle (3) and then through two bearings (2) to guides (6) made integral with the housing. The torque reaction is taken by the rotor. During one revolution of the hydraulic engine each pair of pistons performs four power strokes. The torque is taken from the housing. The fluid is supplied through fixed shaft (7), made in one piece with the rotor. Attached to the lower end of cylinder (1) is gear pump (9), actuated by shaft (8) from take-off gear (7). The body is raised and lowered by means of valve (10).

Fig. 3. High-torque hydraulic engine

Development of high-torque engines will make it possible to construct running wheels, winches and other mechanisms with built-in hydraulic engines (fig. 3.)

B) In a fluid coupling and a torque converter the pump (driving) wheel rotates the working fluid at a high velocity. The kinetic energy of the fluid falling on the turbine (driven) wheel is then converted into mechanical work, creating a torque on the shaft of the wheel being driven. The working fluid is returned from the blades of the turbine wheel to the pump wheel, forming a closed cycle. Hydraulic drives are distinguished by the high rotational velocities of the driving wheel and the working fluid. The pump and turbine wheels have no mechanical linkage between them and are separated by a gap.

One very important feature of a torque converter as compared with a fluid coupling is that the revolutions and torque on the driven shaft can be automatically varied over a very wide range. When an internal-combustion engine is combined with a torque converter it is possible to obtain a very versatile power plant coupled with an increase in the efficiency of the transmission and a decrease in the number of speed gears. A torque converter and a fluid coupling also protect the engine against overloads.

| <== предыдущая лекция | | | следующая лекция ==> |

| Вплив умов транспортування на якість м’яса і шкур | | | Відмітки про ветеринарний огляд при навантаженні, на шляху транспортування і на місці призначення |