Roof renovations

Roof structure is a complete system, one strategic importance subsystem of the building, protects the building from outside mechanical impacts, and isolates the internal room from the outside world. Since the roof is in continuous fight with the weather, therefore it is the most vulnerable part of the building, its maintenance is very important regarding the whole building. In consequence of its damage the main structures, or even the living area can also be damaged.

Not only the main product, the roofing material but the complete roof cladding with accessories have to be taken into account when talking about roof renovation; e.g. ventilation elements, roofing foils, fillers, fasteners and roof safety system (snowfence, roof ladder, sidewalk, etc.). All these ensure the perfect water tightness, necessary load-bearing, adequate ventilation, thus ideal convenience and technically safe solution. It is the most practical to think in the system of a single supplier, as a complete structure functions better, the compatibility and fitting is easier.

12 13

Lindab Seamline ® PLX standing seam roofing Lindab SRP Click pre-seamed roof profile

Coated PLX and plain Aluzinc PLX steel sheets can be used for standing seam roofing solutions. Roof cladding made from boards or strips is fit for coating practically any kind of roof structures. The base material of PLX Lindab Seamline is a hot-dip galvanized steel, coated with Lindab Premium or Lindab Elite extremely thick and durable coating, which keeps its colour efficiently and protects against corro- sion.

The Lindab standing seam roofing materials are present on the con- struction market in a uniquely broad colour palette. In the cases, where the colours have no role, the sheet can be used even without paint coating. Aluzinc is an alloy of aluminium, zinc and titanium, securing perfect protection against corrosion, but, nevertheless, the material remains elastic. In order to facilitate working, the surface of Aluzinc is coated with a pre-treated, thin, so-called STP polymer layer. In line with the “soft” standing seam roof sheets to be seamed at site (traditional PLX), the Lindab SRP Click roof profile is a more recent sheet roofing product. The SRP Click roof sheet is a pre-seamed roof profile manufactured on a production line from hot- dip galvanised “hard” steel sheet with coating, which is, therefore, of high strength and durable, on the one hand, and it can be easily and quickly mounted thanks to its snapped (“click”) joint, on the other hand, and it offers an aesthetic roof cover. In the event of rather simple roof shapes it is a highly economical roof cover. On the face three coating systems (Lindab Classic, Lindab Premium, Lindab Elite) and 17 various colours can be chosen.

The product is available in normal and so-called Design (Dn) profile. The newer Design profile, owing to two intermediate stiffener ribs, is recommended not only on full supporting boarding, but also on battens (c/c maximum 300mm) or on boarding with gaps, in case of roof slope above 22°. Both products are exquisitely adaptable standing seam roofing on both traditional and modern buildings, whether it is a new roof- ing or a renovation.

The displacements occurring necessarily due to thermal moving are secured by the oval fixing openings of SRP Click. The seamed roof sheet fits particularly well modern and Scandinavian style buildings. Generally it can be used for roofs with an incli- nation degree of at least 14°, while it can be applied even for roofing of 7° subject to structural restrictions.

The standing seamed roof sheets can be economically and quickly constructed with the help of modern machines, distrib- uted by Lindab, and by a qualified tinsmith, and their water tightness is one of the best ones among the roofing materials.

Lindab Kft provides 15, 20 and 30 years of warranty in accordance with Lindab Coating systems, in case of professional installation (plain galvanized and Aluzinc: 15 years, Lindab Premium: 20 years, Lindab Elite: 30 years).

15 15

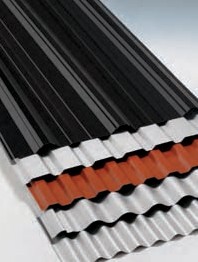

Lindab Coverline ® cladding systems Lindab Coverline ® trapezoid sheets

Lindab Kft offers, with its enlarged profile choice, the most extensive profile palette on the market. Profiles can be ordered with different kind of coating systems (Classic, Premium, Elite) and also in naked (uncoated) galvanised form.

76 colour 76 colour

125

covering width = 1000 mm

Sinus18 Sinus26 Sinus18 Sinus26

18 83,2

colour colour

11,5 77 37 21

LVP8 LVP12 LVP8 LVP12

covering width

drip edge drip edge

colour colour

The Lindab Coverline product line includes profiled sheet products, accessories belonging thereto, as well as cladding systems developed for the application thereof. covering width = 1028 mm

180 180

colour The Lindab trapezoid sheets offer economical and safe solutions and cover for the roof and lateral wall claddings of new buildings and renovations, as well as for both facades and division walls. The extreme durability of the covers is due to the preparation of high quality steel

4015 9 4015 9

LVP35Dn colour

covering width= 900 mm covering width= 900 mm

LTP45

Subject to the expected external appearance, customers’ demand and conceived designs it is possible to opt for Lindab trapezoid sheets, Lindab high profile, Lindab wall cassette or various types of Lindab sandwich panels, as claddings.

All of the products and profiles above are provided with a multi-layer, environment-friendly coating system and can be ordered in diverse colours.

These cladding systems can be used for any kind of buildings, from hypermarkets and industrial sites through logistics and agricultural warehouses, commercial and catering halls to residential buildings.

255

covering width = 1020 mm covering width = 1020 mm

LVP/LTP50Dn

114 40 115

covering width = 920 mm covering width = 920 mm

LTP60Dn

colour colour

Coverline ® high profiles

|

The geometry of the roof surface and the load bearing structure have to be measured exactly, and the conditions of the existing materials should be carefully checked before the roof renovation works. One of the several great advantages of the Lindab tile effect sheets is its light dead load, weights about 5 kg projected to a m2, thus meaning very low extra load for the roof structure, load-beraing walls and foundations and low extra spending to our pocket cash. The new tile effect roofing does not require reinforcement or renovation of the old supporting structure in most of the cases. Furthermore it offers the opportunity of installation on existing slated roof (flat or wave slate) without the removal and transportation of the highly costy and hazardous waste, asbestos roof slate. Lindab steel roofs are the most ideal in case of renovations owing to their low dead load, high quality Swedish steel base material, special drip edge sidelaps and large sheeted roofing technology. Remarkable working hour reduction is allowed by the large sheet sizes, the production to exact geometry and the fast and easy assembly.

The geometry of the roof surface and the load bearing structure have to be measured exactly, and the conditions of the existing materials should be carefully checked before the roof renovation works. One of the several great advantages of the Lindab tile effect sheets is its light dead load, weights about 5 kg projected to a m2, thus meaning very low extra load for the roof structure, load-beraing walls and foundations and low extra spending to our pocket cash. The new tile effect roofing does not require reinforcement or renovation of the old supporting structure in most of the cases. Furthermore it offers the opportunity of installation on existing slated roof (flat or wave slate) without the removal and transportation of the highly costy and hazardous waste, asbestos roof slate. Lindab steel roofs are the most ideal in case of renovations owing to their low dead load, high quality Swedish steel base material, special drip edge sidelaps and large sheeted roofing technology. Remarkable working hour reduction is allowed by the large sheet sizes, the production to exact geometry and the fast and easy assembly. The new roofing material can be made of Lindab Coverline trapezoid sheet in case of steadings or simple farm-buildings, Lindab Topline coated or Roca stone coated tile effect sheet, while SRP Click in case of elegant family or public buildings, or PLX seamed flat sheet roofing in case of the most diverse roof shapes.

The new roofing material can be made of Lindab Coverline trapezoid sheet in case of steadings or simple farm-buildings, Lindab Topline coated or Roca stone coated tile effect sheet, while SRP Click in case of elegant family or public buildings, or PLX seamed flat sheet roofing in case of the most diverse roof shapes.

183,5

183,5

CFoevdeőrsinzéglewsisdéthg = 1100

CFoevdeőrsinzéglewsisdéthg = 1100 The Lindab Seamline steel sheets are prepared from a special quality soft steel, PLX, representing of a particularly high quality. The stand- ing seam roof system allows the construction of expressly elegant buildings of individual appearance. One of the biggest advantages of standing seamed sheet covering is its flexibility.

The Lindab Seamline steel sheets are prepared from a special quality soft steel, PLX, representing of a particularly high quality. The stand- ing seam roof system allows the construction of expressly elegant buildings of individual appearance. One of the biggest advantages of standing seamed sheet covering is its flexibility.

SRP SRP Dn

SRP SRP Dn

Through combining aluminium, zinc and steel we will receive a very nice, argent look, non-rusting surface and roof requiring a minimum of treatment, with a lifespan extremely long.

Through combining aluminium, zinc and steel we will receive a very nice, argent look, non-rusting surface and roof requiring a minimum of treatment, with a lifespan extremely long.

The Lindab trapezoid sheets and sinus profile, manufactured and distributed by Lindab, serve as base for lightweight cladding systems. The various profile types, rib heights, sheet thicknesses and diverse colours secure roof shells or wall claddings of technologically excellent quality and, at the same time, aesthetic appearance, and as final result they “dress” the whole building.

The Lindab trapezoid sheets and sinus profile, manufactured and distributed by Lindab, serve as base for lightweight cladding systems. The various profile types, rib heights, sheet thicknesses and diverse colours secure roof shells or wall claddings of technologically excellent quality and, at the same time, aesthetic appearance, and as final result they “dress” the whole building. 113,5

113,5

sheets, whose basic material is hot-dip galvanised steel in order to prevent corrosion.

sheets, whose basic material is hot-dip galvanised steel in order to prevent corrosion.

16 17

16 17 Lindab Coverline ® trapezoid sheets

Lindab Coverline ® trapezoid sheets