Practical measures to increase the fatigue strength

It is recommended to accept the following measures to increase the fatigue strength under the details construction, working in the conditions of the variable stresses arising: 1. Apply more homogeneous materials with the fine-grained structure, free from the internal concentration center (cracks, the gas bubbles, the non-metallic inclusions and so on). 2. Add the details such outlines under which the stress concentration would be decreased. The transitions from one dimension to the second one without the passaged curves must not be admitted. In some cases it is recommended to apply special unloading slots i.e. the stress deconcentrator. So, for example, if we make a smooth gorge in a more thick detail part at the place of the sharp transition (Fig. 11.16), the local stresses decrease sharply.

Fig. 11.16 Fig. 11.17

3. Treat the detail surface carefully up to polishing eliminating the smallest slots because they can be the beginning of future fatigue cracks. 4. Apply special increasing methods of the fatigue strength (the surface hardness, training the details by the momentary increased loads and so on). The term of the details functioning can be increased in 2-3 times under modest additional expenses by the surface hardness. It means that the machines output can be doubled and trebled. It can be seen from this example that a large economical effect can be received by the right construction and the technological treatment of the machine details. Example 1. Calculate the fatigue of the shaft with fillet г=5 мм (Fig. 11.17). The bending moment М =3 кNм, acts at the shaft cross section, the twisting moment Т =4кNм. The shaft material is steel 45 with The shaft surface is polished because the coefficient of the smooth influence is Accept that the bending stresses change by a symmetrical cycle and in torsion – by pulsating. Solving.

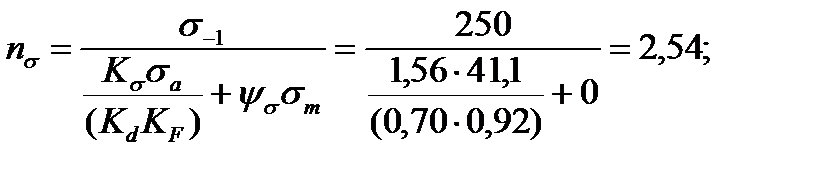

Calculate the amplitude and average cycle stresses: Determine the stress concentration coefficients. Under Then we get by the formula (11.10) Kσ =1+0, 7 (1, 8-1)=1, 56. The influence coefficient of the absolute dimensions for the shaft d=90 mm. we have from Fig. 11.14 (the curve 1) Kd =0, 70. In torsion we accept Kd =0, 70. Calculate the strength of safety: a) on the fatigue strength:

b) on the yield point:

As we see, the minimum strength of safety is received on the fatigue strength n =2, 35. It must be compared with the normative factor of safety nadm which value is determined according to the reference data. Supposing that the precision of determining the stresses is average we can accept n1 =1, 3, and supposing the usual technological level, the average degree of the material homogeneously and the average detail dimensions we will accept n2 =1, 5. Supposing the average detail responsibility we accept n3 =1, 3. The general normative strength of safety is

Thus, in the given example the actual strength of safety is a bit less than normative. Therefore it is necessary either to increase the diameter or to apply more strong steel.

|

=610 МPа,

=610 МPа,  =360 МPа,

=360 МPа,  =250 МPа,

=250 МPа,  =210 МPа,

=210 МPа,  =150 МPа.

=150 МPа. (see Fig. 11.15).

(see Fig. 11.15). MPа,

MPа,

=0;

=0;  =41, 1 МPа,

=41, 1 МPа,  =13, 85 МPа.

=13, 85 МPа. and

and  from the diagram in Fig. 11.8 we have (Kσ )0 = 1, 8. Taking into account that in our case we have

from the diagram in Fig. 11.8 we have (Kσ )0 = 1, 8. Taking into account that in our case we have  and using the diagram of Fig. 11.11 we find the correction coefficient ξ =0, 7.

and using the diagram of Fig. 11.11 we find the correction coefficient ξ =0, 7.