LATHE OPERATIONS

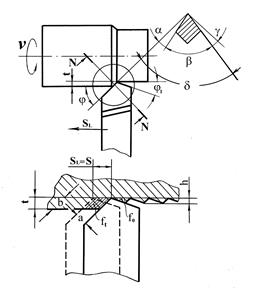

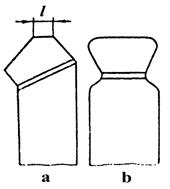

Purpose of the work. To study the basic principles of lathe operations, design and working principles of a screw-cutting lathe and a single-spindle semi-automatic lathe, to make acquaintance with lathe cutting tools and basic operations involved, to study the effect of cutting regime upon quality of finished products, to determine the automation level influence on machining productivity. Theory. Lathe cutting is the most widespread among metal machining operations. The lathe is an important machine shop tool. Its share in the total machine-tool stock runs into 30…40%. Lathe machining is characterized by rotational movement (the main movement) and feed movement: longitudinal and transverse (cross). Operations performed on a piece of work in the lathe fall into two general classifications: external (turning, facing, knurling, external thread cutting, etc) and internal operations (drilling, reaming, boring, internal threading, etc). A work surface should form a rot table body shape while, for instance, turning, or plane while facing. Engine lathes are classified as the first group according to ЭHИMC's classification. The group is subdivided into turning, screw-cutting, turning and boring, multiple-tool, turret, automatic and semi-automatic, special and specialized lathes, etc. Cutting regime in lathe machining is primarily defined by the following values: cutting speed V, feed SL, Sc and cutting depth. Cutting speed is determined as a speed of a work surface dot removed to the utmost from the rotation axis. The distance a cutting edge will advance along a work piece (into it) per unit time or in one complete revolution is called the feed and labeled by S, mm/min or mm/r. The feed may be either longitudinal SL or cross (transverse) Sc. The cutting depth t, mm, is the distance between a work surface and already machined surface measured in perpendicular to the last. In lathe machining the cutting depth is determined by the formula: t = 0.5(D – d), where D is work piece diameter; d is machined diameter. The parameters of cutting regime influence significantly on cutting performance and finished product’s quality. Cutting speeds, for instance, determine the heat quantity, released in machining, chip built-up intensity, strain hardening of a work surface, chip formation character, wear of cutting tools and other phenomena. Feed and cutting depth affect on force system, work, consumed in machining, heat phenomena, etc. The quality of finished products is primarily determined by cutting regime (especially by cutting speed and feed) and cutting tool geometry. Two consequent positions of a tool, which is advanced past a workpiece in one complete revolution, are depicted in Fig. 6.1. Turning is afforded by the combination of several movements (V and SL). Hence, the true value of a cut layer f is smaller than the nominal one (ft = ab) by f0 – factor of fins cross-sectional area. Fins’ height mainly determines finished roughness and accuracy rating. The height may be decreased by reducing the side cutting-edge and the end cutting-edge angles j1 (Fig. 6.1), increasing the nose radius, reducing the longitudinal feed, application of additional cutting edges, as well as special finish-machining tools (Fig. 6.2).

Fig. 6.1. The cutting edge angles and cross-section of cutting layers: a- clearance angle; b - wedge angle; g - top rake angle; d - cutting angle;

Fig.6.2. Cutting tools: a – with additional cutting edge; b – finishing

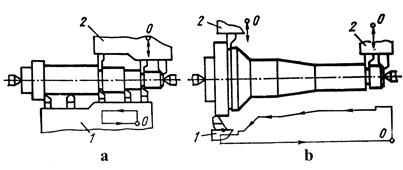

The chip built-up formation (especially in cutting of plastic materials) and its periodical spalling (spelling) also deteriorate the surface quality. The intensity of the process rises as the cutting speed increases up to 18…30 m/min (depending upon other conditions). In further cutting speed increase (above 40…50 m/min) the built-up formation is interrupted and surface quality improves. Besides mentioned factors the surface quality is also affected by physical and mechanical properties of a work material, wear of a tool, cutting fluid type, stiffness of a technological circuit. Automatic and semi-automatic lathes are usually employed in mass-production for reducing the manual share in labor input. A lathe, which provides all operations, except mounting of a workpiece and removal of a finished article, to be carried out automatically, is called semi-automatic lathe. An automatic lathe performs all the operations exclusively without human intervention. The most wide spread single-spindle semi-automatic lathe has predominantly horizontal spindle axis and at least two carriages – longitudinal and transverse (Fig 6.3, a). The lathes facilitate working of, for instance, step shafts. The semi-automatic lathes are divided into multiple-tool and profile-turning machines. In the first machines every work surface is machined by a special tool. In the second case, machining is carried out by a single cutting tool, advancing along a given trajectory (Fig. 6.3, b).

Fig. 6.3. Machining of step shafts in multiple-tool (a) and profile-turning (b) semi-automatic lathes

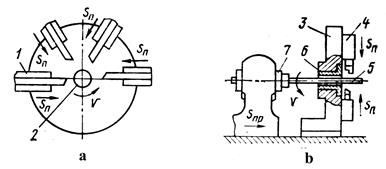

Horizontal single-spindle bar machines are the most widely used automatic lathes (bar is the workpiece). They may be as follows cutting off, longitudinal turning and turret lathes. In the cutting off automatic lathes cutting operations are performed while tools are involved in transverse movement (Fig. 6.4, a). The absence of longitudinal feed limits the field of their application. In case of the longitudinal-turning, automatic machines the main movement (rotation) and longitudinal feed of the workpiece 5 are provided by the spindle 7. The tool carriages 4, supported by the pillar 3 with the bushing 6, move as a unit along the bedways (Fig. 6.4, b). More intricate and long parts may be produced in such lathes.

Fig. 6.4. Machining in single-spindle automatic lathes: a – cutting off,

The most intricate parts are machined in the turret automatic lathes with a hexagon turret, mounted on longitudinal carriage. The hexagon turret has several built-in transverse carriages and, different cutting tools. Automatic and semi-automatic lathes of other designs, for example, multiple-spindle, are also employed in mass production.

|