Application area of Lindab halls

warehouses, logistic centres, storages • production, assembly plants, work-houses • agricultural halls: open sheds, closed barns, grain storage, machinery sheds, food plants • animal keeping: poulty buildings, stables, pig-farm, riding-hall and feed storage • service buildings: technology, engineering and social blocks, offices, car showrooms, education buildings • private buildings: shop, office, workshop, steading, storage.

Lindab lightweight structure halls: Lindab SBS building system (~50-250m2) Lindab lightweight structure halls: Lindab SBS Maxi - middle sized halls (~200-2000m2)

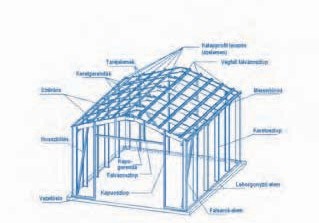

The wall frame structure of the building is made of Lindab Construline cold roll-formed lightweight beams, placed after each other according to a 1m module size. Thus 18-20m long, 200-250m2size groundspace lightweight structure buildings can fast be put into shape.

Assembly guide and drilling templates help the installation of products manufactured and formed in a customised size. In this way a building of a smaller size (3-6m width) can be installed even in a DIY system with appropriate sense for technology and installation experience. In the event of larger sizes (over a span of 6-8m) it is recommended to commission a Lindab specialised constructor.

The buildings prepared from Lindab SBS system can be applied for various functional purposes, with identically nice architectural image. In this way it can be used for the building of a garage, shop, warehouse building, emergency station, doorkeeper buiding, temporary mobilisation facilities, but even a birdhouse in a zoo. Lindab SBS Maxi as the 2013 improvement of the complete Lindab SBS building system is a larger sized, lightweight, fully hot-dip galvanized, complete Lindab hall building: available with a free span of maximum 18m, groundfloor area of 200-2000m2, with eaves height up to 6m.

The connections are made with metric, hexagonal bolts with nuts, and special welded steel accessories (e.g. anchoring bolts, eaves and ridge elements). The special structural design method of the SBS Maxi is developed optimally on the base of Eurocode standards, laboratory tests and highly developed numeric calculations. It guarantees technically excellent, durable solution for owners and operators. With heat insulated or non-insulated, trapezoid sheet or sandwichpanel roof and wall cladding system the main field of utilisation is the industrial and agricultural halls with a ground floor area of 200-2000m2, furthermore warehouses, plants, work-houses and service buildings (porter’s lodge, showrooms, education buildings), where the use of durable hot-dip galvanized steel elements, the fast production and installation, the simple and economic construction are important.

Complete, adoptable frame drawings are available for inquirers and architests in standard frame sizes (9-12-15-18m span, 3-4.5-6m eaves height), furthermore Lindab ensures the individually optimized design of frame structures and technical documentation for the complete hall buil- ding in case of orders.

26 27

Lindab lightweight structure halls: Lindab Systemline ® hall systems (over ~1000m2) Integrated systems: Cladding systems for halls with reinforced concrete frame

The hall system offers an excellent solution for the economical and high- standard implementation of the hall structures of plant halls serving a great variety of purposes, servicing and warehouse buildings, sports halls, cold stores, agricultural buildings, etc.

on the buildings and halls with pre- fabricated frame or frame from monolithic reinforced concrete.

Typically the following secondary supporting and cladding systems can be used for halls with reinforced concrete frame:

• Z-purlin row and cladding with tra- pezoid sheets (one or two layers, heat insulated), in the event of a roof inclination of at least 10%;

• Z-purlin row and sandwich panel cladding, in the event of a roof inclination of at least 7%;

• high-profile trapezoid sheet and soft covering; even in the event of a mini- mum of inclination (3%).

28 29

Integrated systems:

|

24 25

24 25 SBS (Small Building System) buildings system developed by Lindab is an easy-to-assemble, aesthetic appearance lightweight building system designed for small span (3-13m) and low eaves height (2.5-4.0m) buildings.

SBS (Small Building System) buildings system developed by Lindab is an easy-to-assemble, aesthetic appearance lightweight building system designed for small span (3-13m) and low eaves height (2.5-4.0m) buildings. The possibility of unique and aesthetic outdoor appearance is enabled owing to the broad colour and shape range of the Lindab cladding systems.

The possibility of unique and aesthetic outdoor appearance is enabled owing to the broad colour and shape range of the Lindab cladding systems. An SBS building can be manufactured in heat insulated or non-insulated versions, as per demand. The doors and windows, like the garage doors can be designed with a minimum of restrictions, since the structure can be flexibly modified according to the ideas of the customer. Design will be assisted by detailed drawings prepared in advance, heat and vapour calculations, as well as by design software (SBSSoft).

An SBS building can be manufactured in heat insulated or non-insulated versions, as per demand. The doors and windows, like the garage doors can be designed with a minimum of restrictions, since the structure can be flexibly modified according to the ideas of the customer. Design will be assisted by detailed drawings prepared in advance, heat and vapour calculations, as well as by design software (SBSSoft).

The primary frames of the Lindab SBS Maxi are made of built-up cross- sections formed by double, lightweight, hot-dip galvanized C profiles with corner rods and horizontal tie-rod. Free span of 9-18m, eaves height with 3-6m, single air-space hall buildings can be realized with this solution. The spacing of the frames can vary between 3 to 6m, there are no limitations for the total length of the building, even 100 to 200 m long SBS Maxi hall buildings are available if appropriately dilatated.

The primary frames of the Lindab SBS Maxi are made of built-up cross- sections formed by double, lightweight, hot-dip galvanized C profiles with corner rods and horizontal tie-rod. Free span of 9-18m, eaves height with 3-6m, single air-space hall buildings can be realized with this solution. The spacing of the frames can vary between 3 to 6m, there are no limitations for the total length of the building, even 100 to 200 m long SBS Maxi hall buildings are available if appropriately dilatated.

Due to its advantageous properties Lindab’s lightweight hall system is high- ly popular among builders, designers and constructors alike.

Due to its advantageous properties Lindab’s lightweight hall system is high- ly popular among builders, designers and constructors alike. The primary steel frame, the secondary structure, the roof and wall clad- ding systems, as well as the raingutter system are the main sub-systems of “customised” hall structures adjusted to the market demands. The steel frames structures, having individually optimised design, are available with hot roll-formed profile frames, welded I-profiles of variable cross-section or truss girder structures aligned with procurers’ demands. Numerous further variants of these main types are possible, such as side-aisles, intermedi- ate storey, crane-runway, etc. The secondary load bearing elements (roof purlins, wall beams), are hot-dip galvanised, high load-bearing, lightweight Z and C profiles in general.

The primary steel frame, the secondary structure, the roof and wall clad- ding systems, as well as the raingutter system are the main sub-systems of “customised” hall structures adjusted to the market demands. The steel frames structures, having individually optimised design, are available with hot roll-formed profile frames, welded I-profiles of variable cross-section or truss girder structures aligned with procurers’ demands. Numerous further variants of these main types are possible, such as side-aisles, intermedi- ate storey, crane-runway, etc. The secondary load bearing elements (roof purlins, wall beams), are hot-dip galvanised, high load-bearing, lightweight Z and C profiles in general. The roof cladding systems offer numerous possibilities: from the single layered trapezoid sheet roofs, the multi-layered, heat insulated systems to pre-fabricated sandwich panels with all the accessories in each case (fas- teners, sealings, flashings, etc.). The diverse appearance of the facade is guaranteed with Lindab wall cladding systems, thus offering solutions for traditional facades and the most up-to-date shaping alike (trapezoid sheet, sinus sheet, wall cassette, sandwich panel, etc.), while the wide range of system accessories make the whole hall buildings complete (raingutter, industrial door, roof safety system).

The roof cladding systems offer numerous possibilities: from the single layered trapezoid sheet roofs, the multi-layered, heat insulated systems to pre-fabricated sandwich panels with all the accessories in each case (fas- teners, sealings, flashings, etc.). The diverse appearance of the facade is guaranteed with Lindab wall cladding systems, thus offering solutions for traditional facades and the most up-to-date shaping alike (trapezoid sheet, sinus sheet, wall cassette, sandwich panel, etc.), while the wide range of system accessories make the whole hall buildings complete (raingutter, industrial door, roof safety system).

When using the thin-wall steel sheet products and light Z-C-U profiles manufactured and distributed by Lindab, cladding systems, both economical and excellent in technology, can be designed and constructed

When using the thin-wall steel sheet products and light Z-C-U profiles manufactured and distributed by Lindab, cladding systems, both economical and excellent in technology, can be designed and constructed

Depending on the functional, technological and aesthetic demands it is easy to select the most appropriate solution regarding both technology and economy.

Depending on the functional, technological and aesthetic demands it is easy to select the most appropriate solution regarding both technology and economy.